OUTOTIVE RECOVERY offers modular equipment and improvements to existing clarification equipment through a hydraulic-mechanical process, achieving an efficiency of over 97% for large flows, trapping ultra fines and foams. Complementing also with large volume mechanical dehydration equipment.

We innovate in integrated solid/liquid separation process systems in an efficient, effective and environmentally friendly way.

No footprint required.

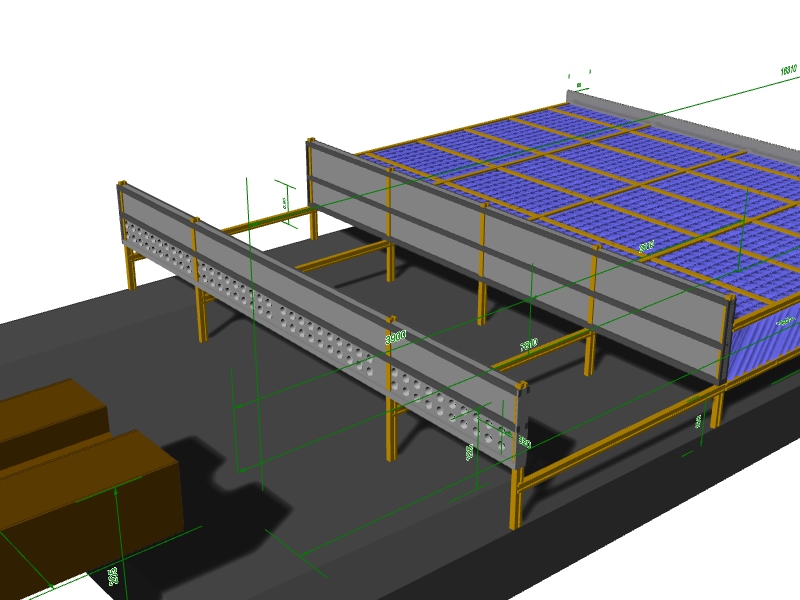

Only the installation of supporting structures is required inside the existing equipment.

There is no consumption of electricity.

Minimum maintenance.

Minimum intervention of operators for its operation.

Operational flexibility against changes in flow and concentration of Suspended Solids.

Installation of support and filter systems have minimal impact on the operation.

Benefits

- Increase in the retention efficiency of ultrafine solids of less than 1 micron, obtaining an overflow with less turbidity compared to a time prior to the modification.

- Reduction of the consumption of reagents such as flocculants or coagulants to 0.

- It is designed for a minimum of 90% retention of fine solids, depending on each case.

- It retains the foam and improves the quality of recovered water.

Services

Clarification

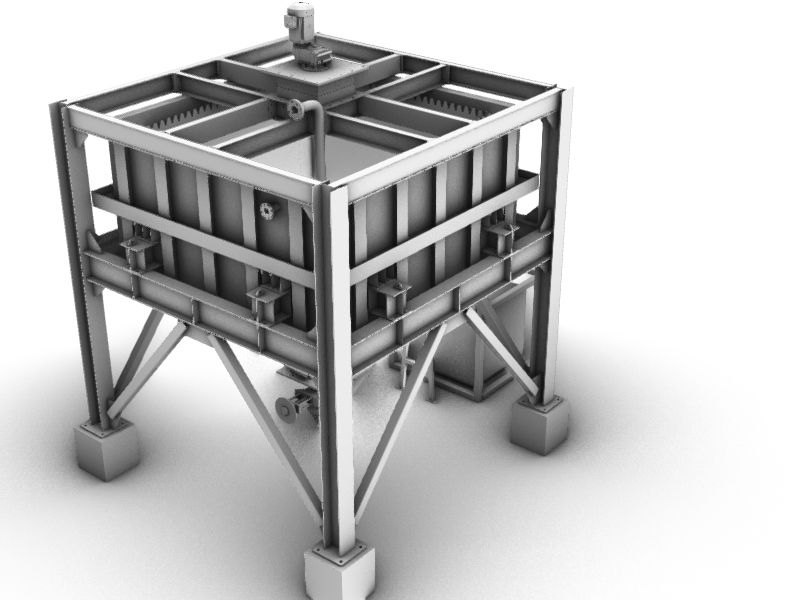

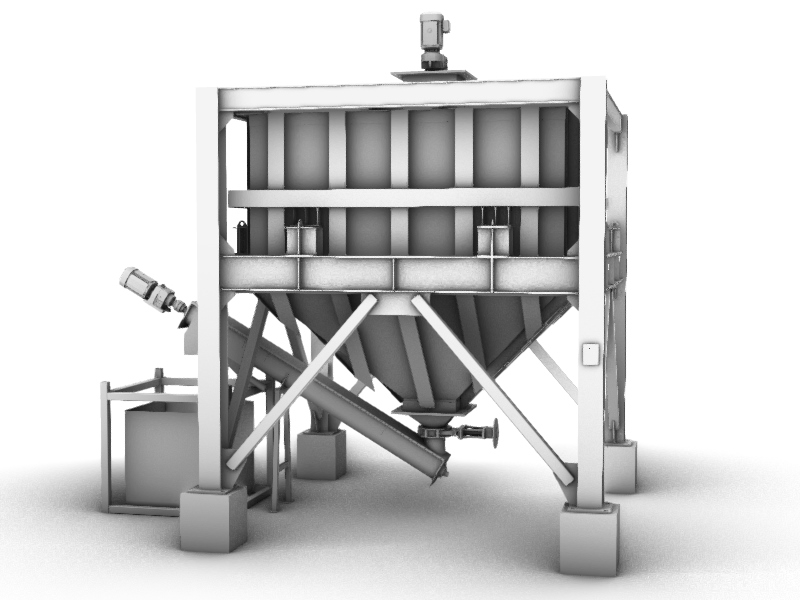

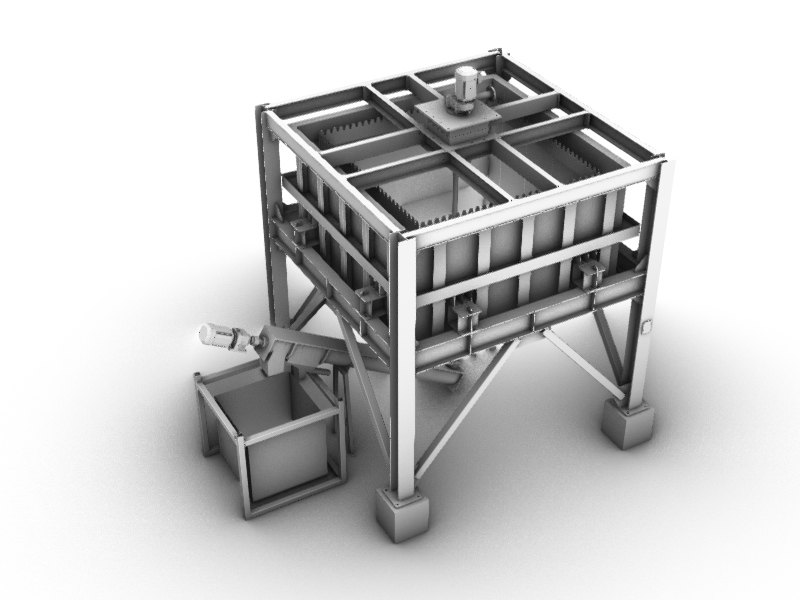

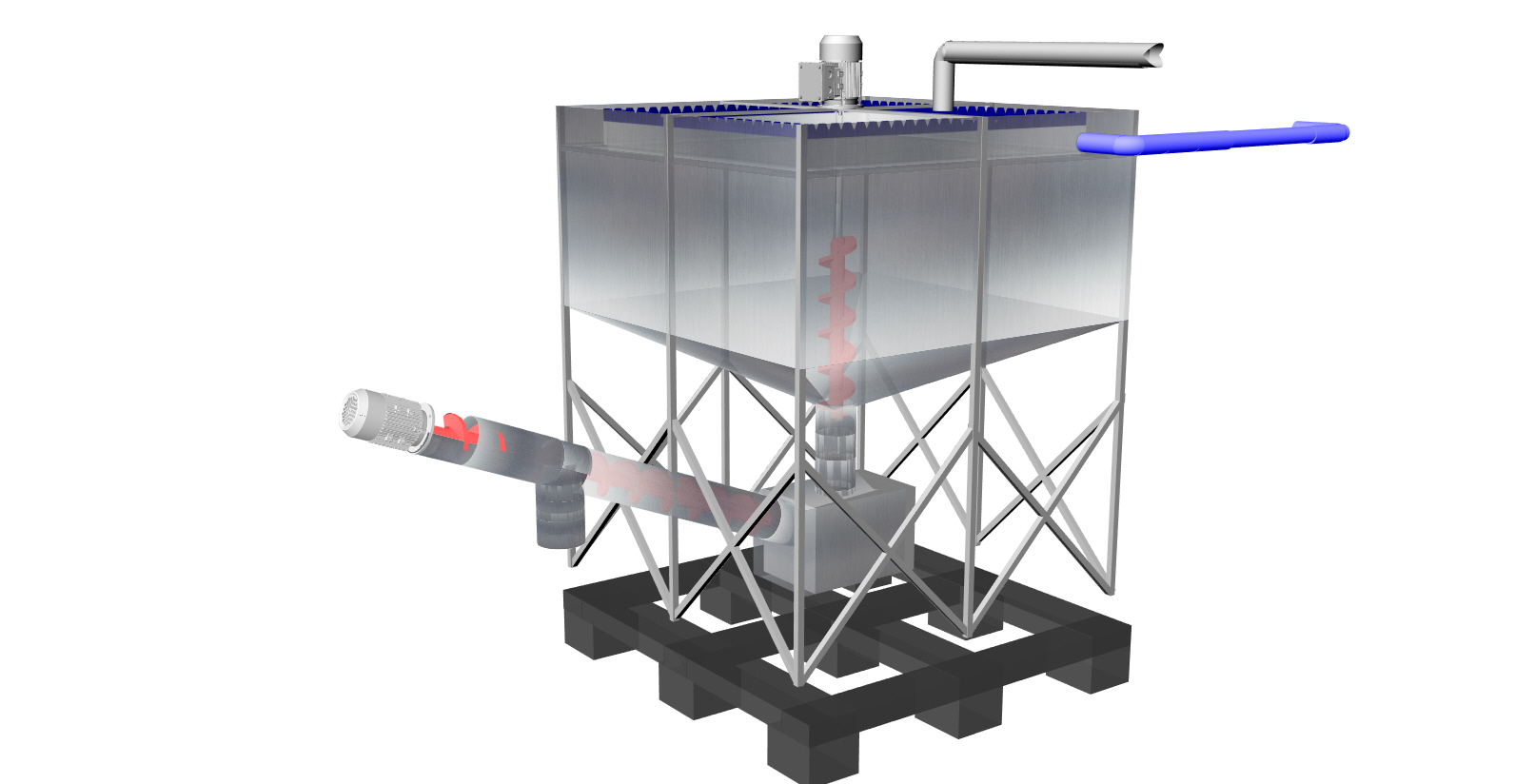

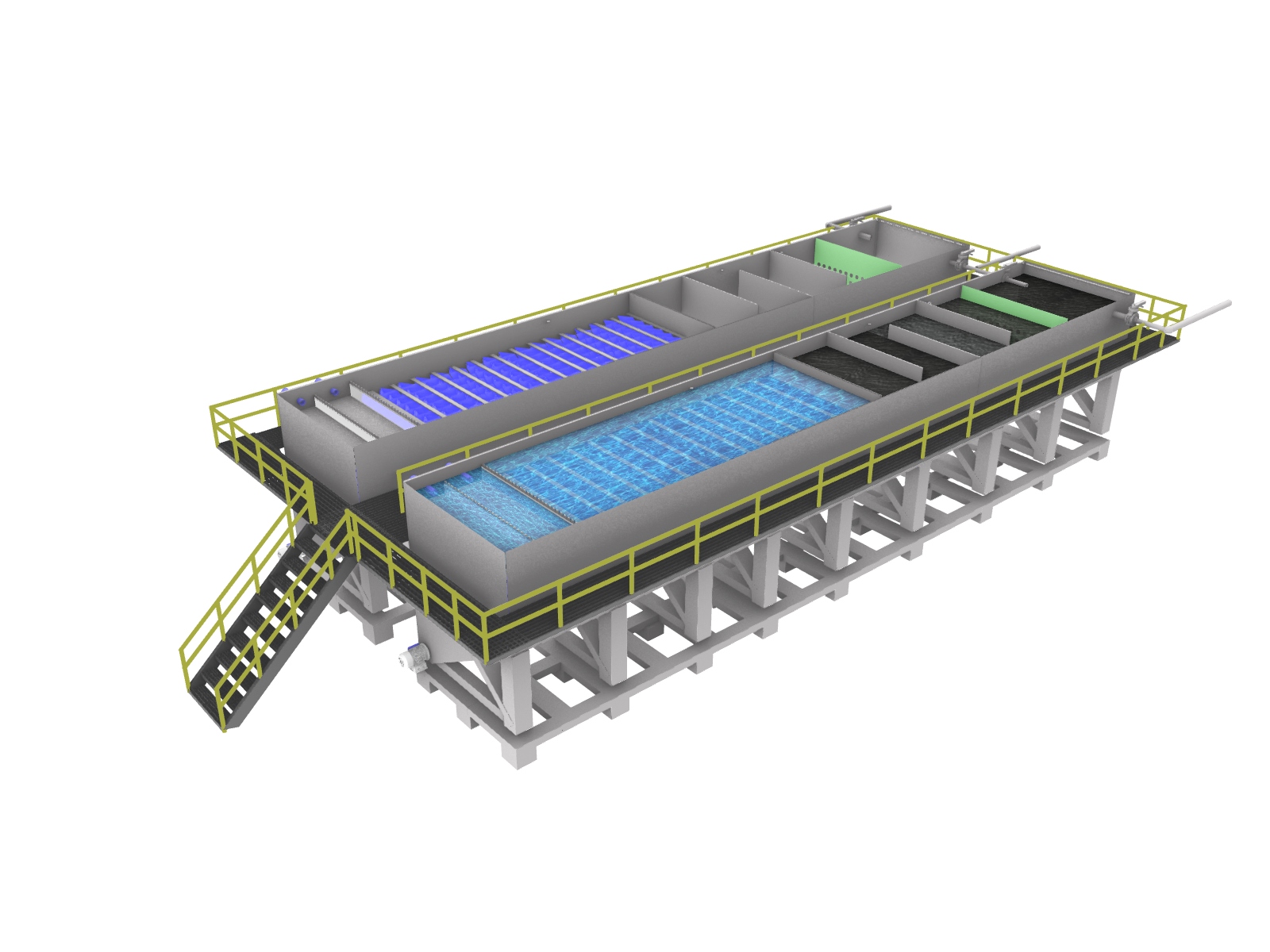

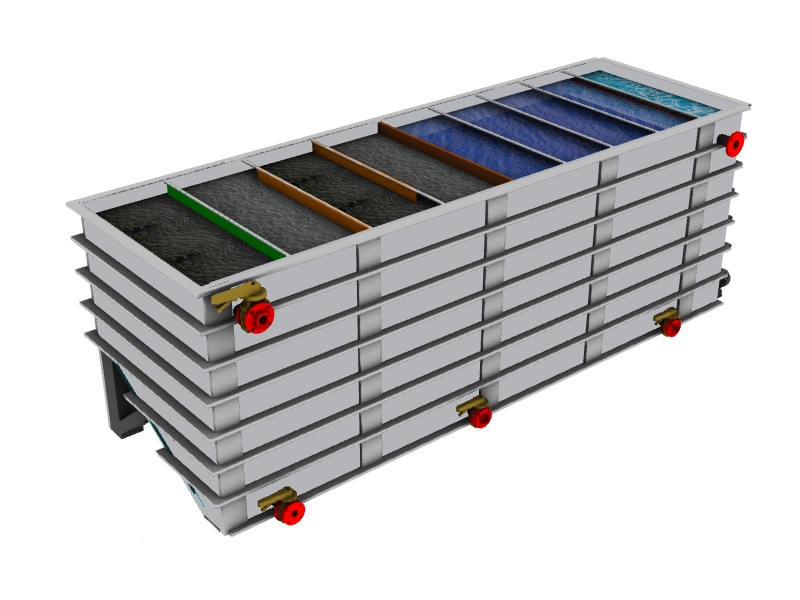

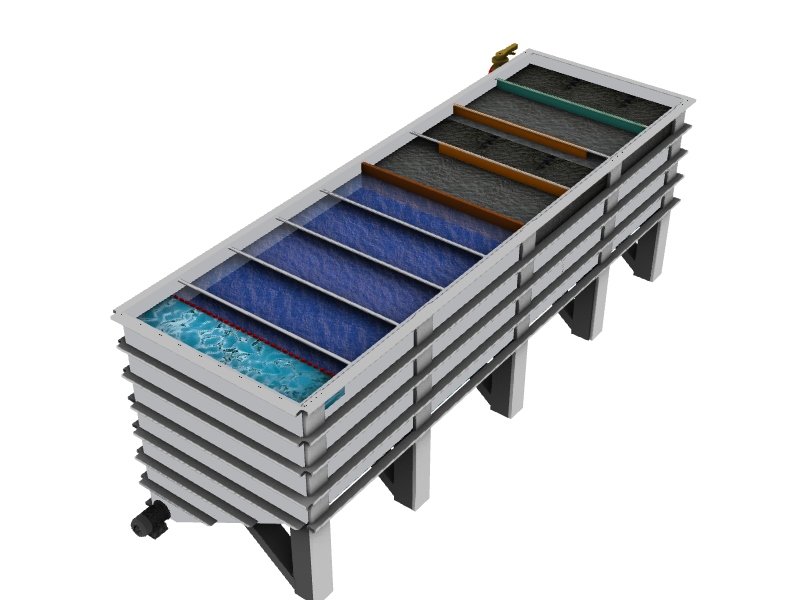

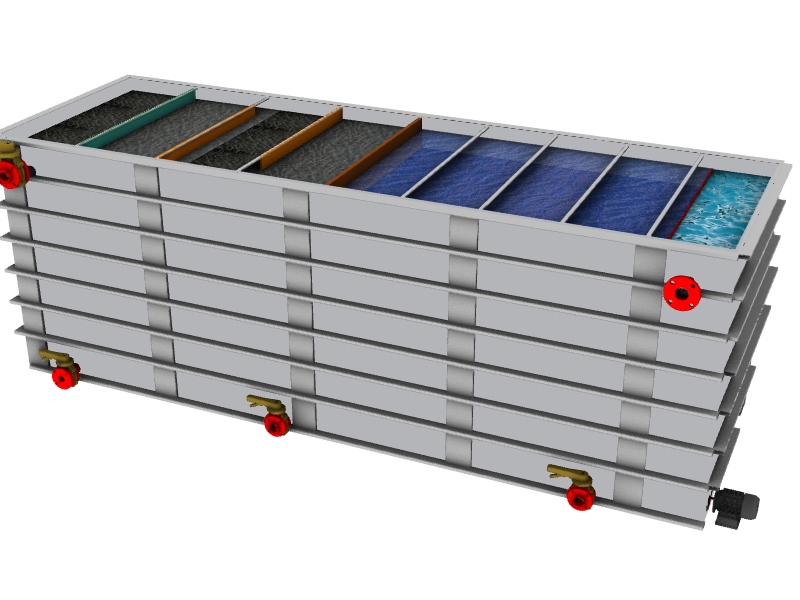

Matrix Clarifier

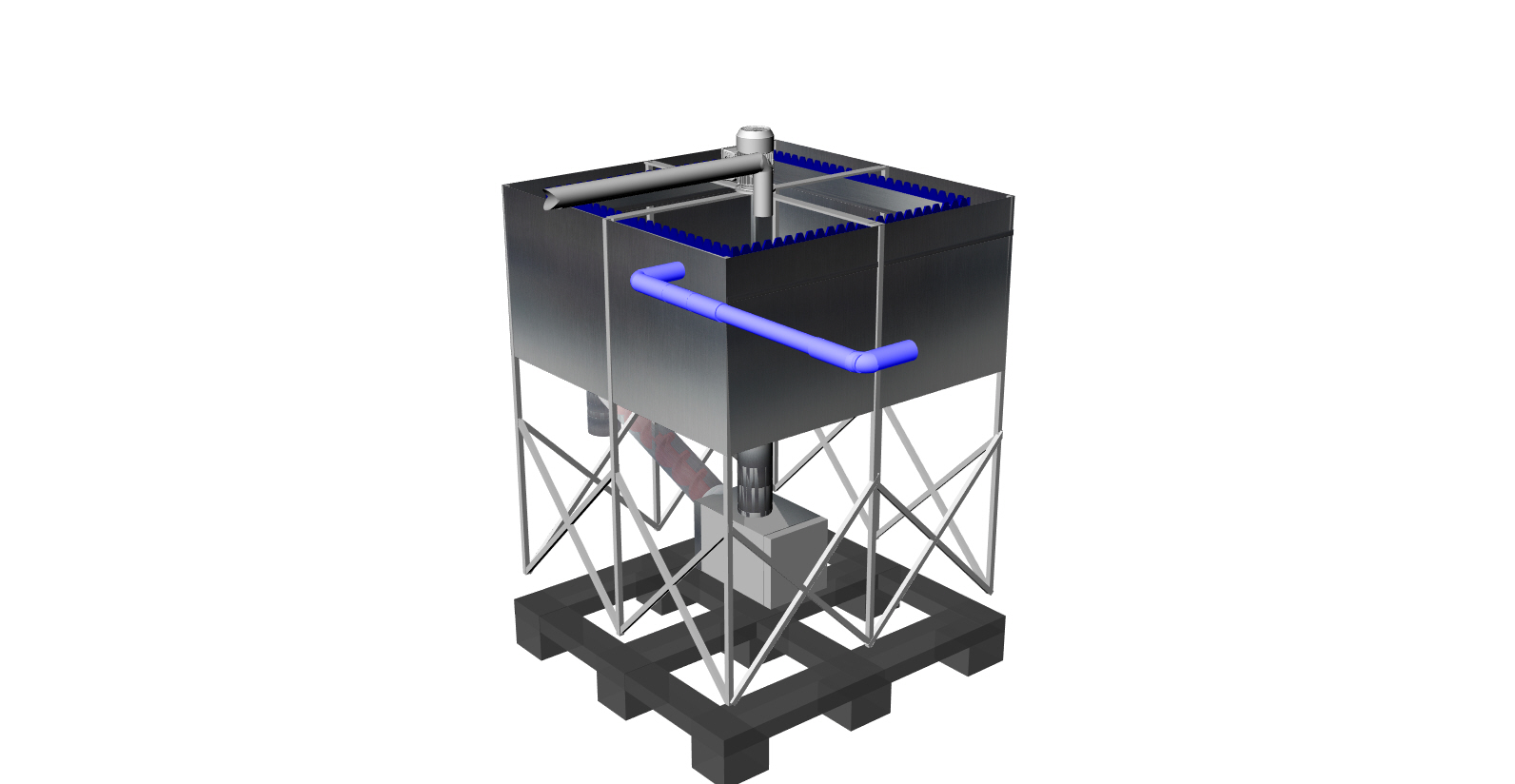

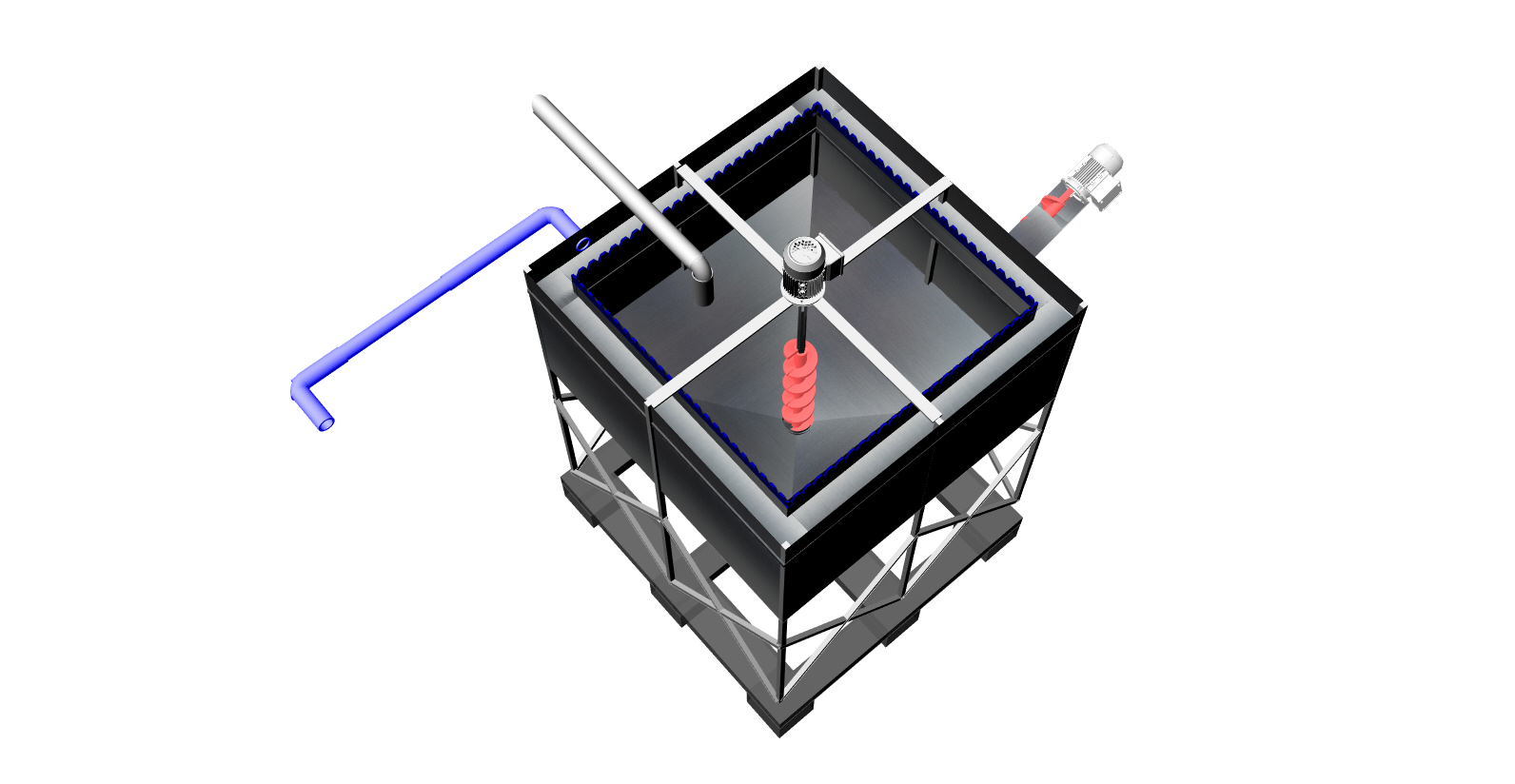

Clarifier to treat large flows, compact, transportable with rectangular geometry, modular and easy plug and play. Configurable for any stage of the process.

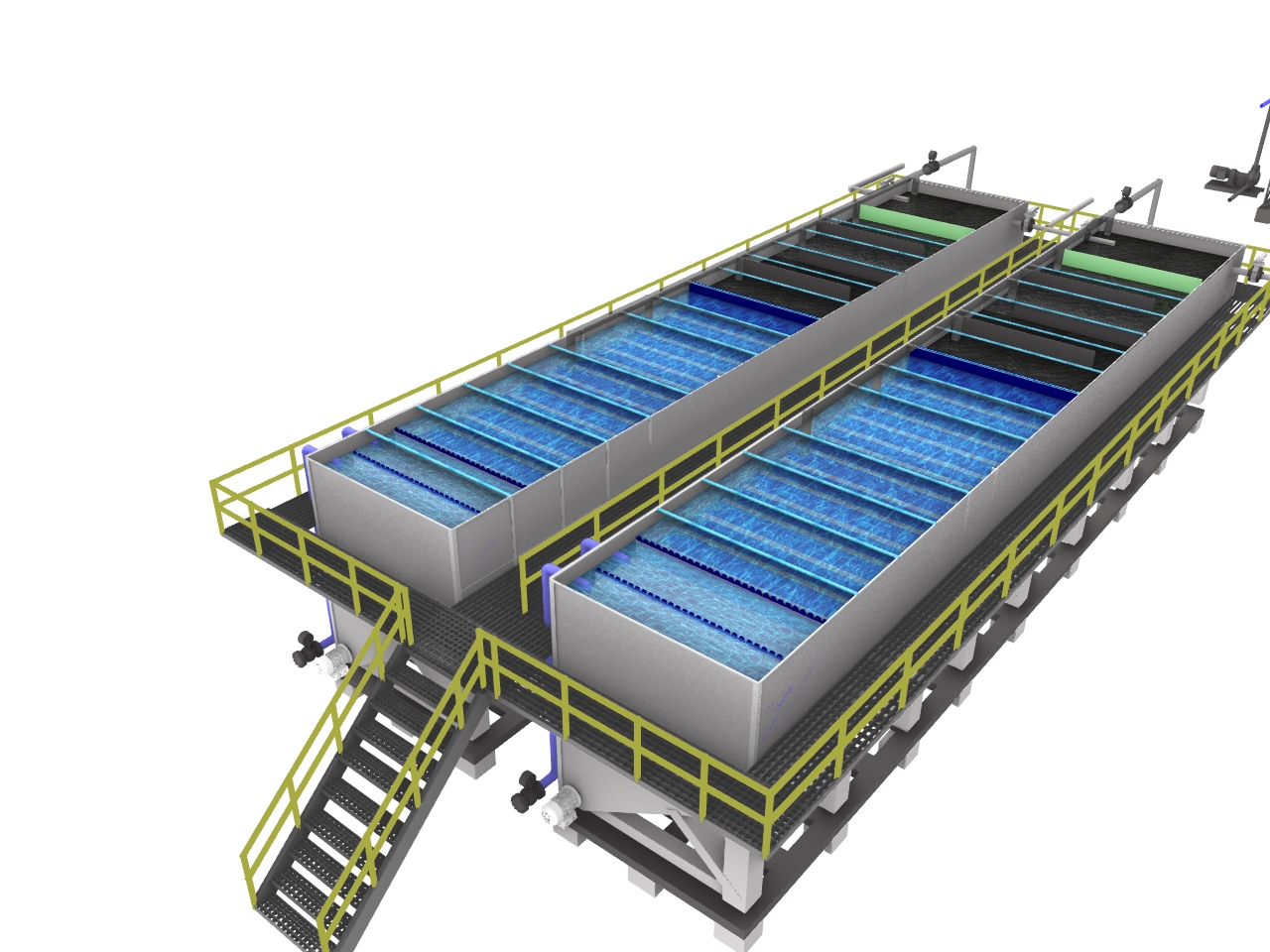

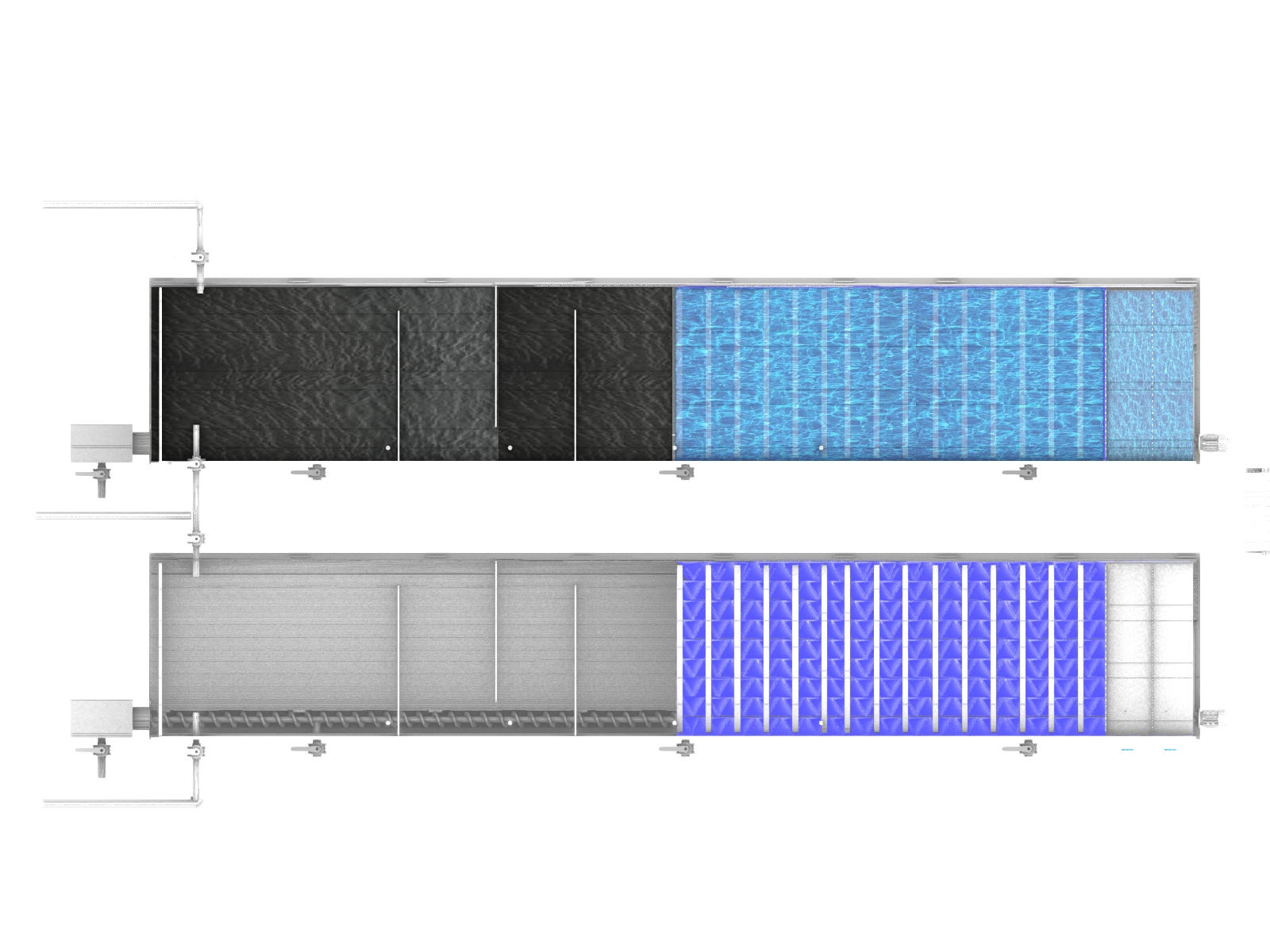

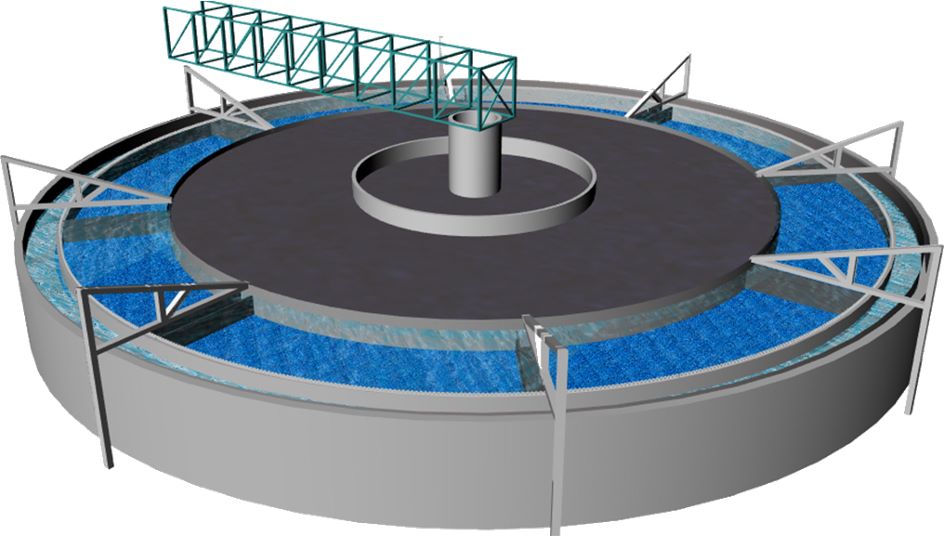

InnerMatrix Clarifier

INNERMatrix Clarifier is the internal configuration of our technology applied to existing equipment such as circular clarifiers and reclaimed water pools where maximum clarification is required without chemical products for sanitary, industrial, mining equipment, among others.

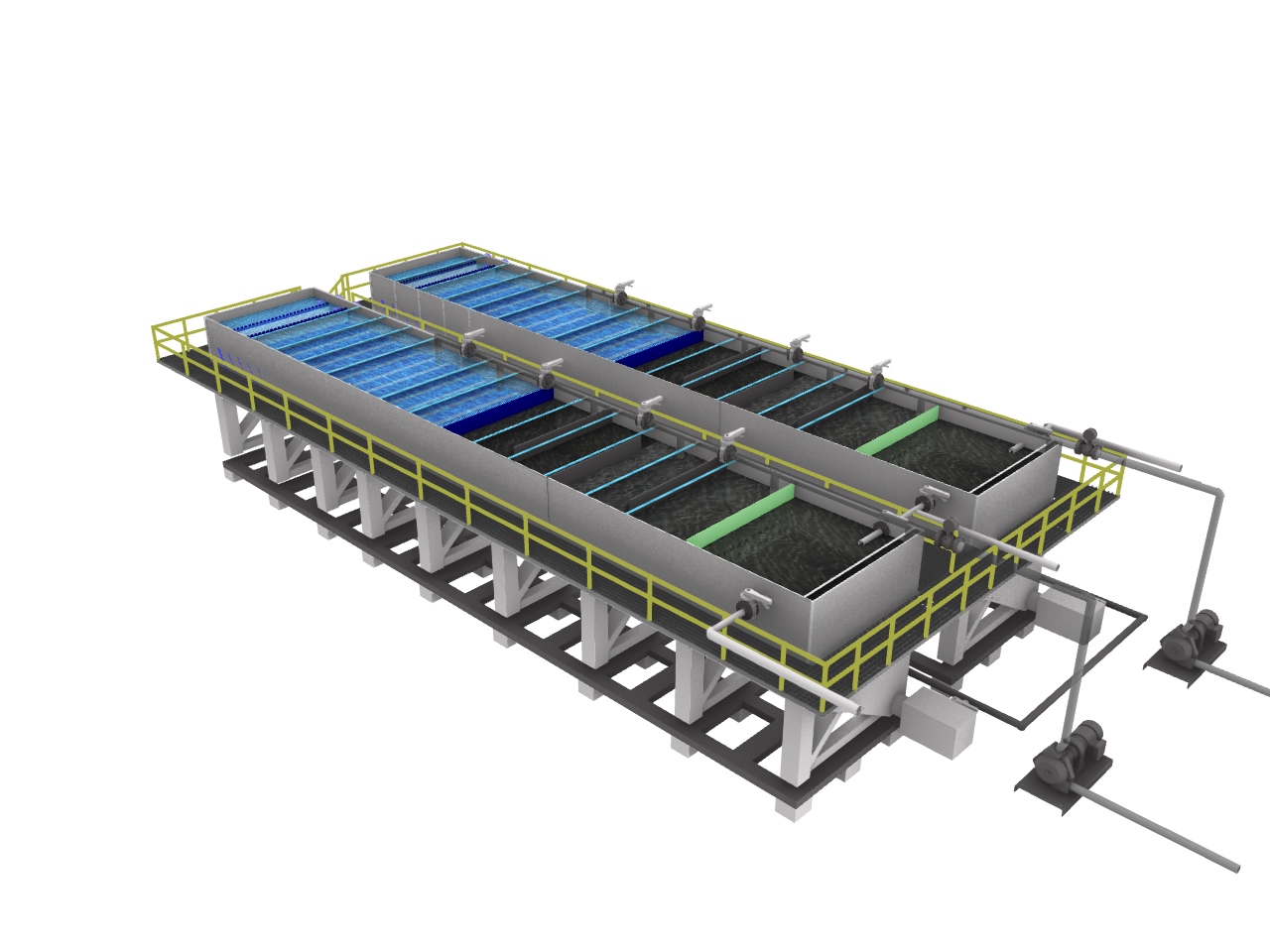

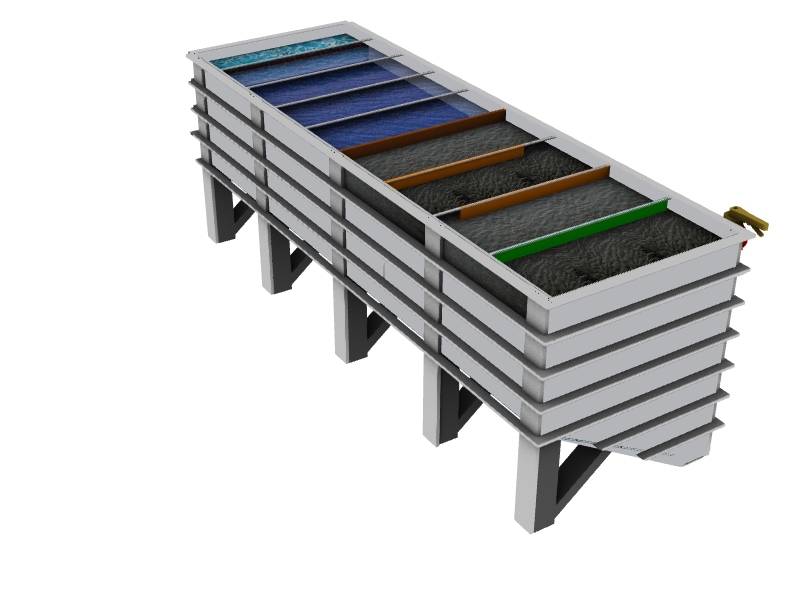

Dehydrators

Compact and modular equipment tailored to the needs of the client, under the hydraulic-mechanical process modality, managing to remove solids with up to 5% humidity where the overflow returns to the clarification process.